MR for the Mining & Resources Industry

3D Walkabout is an Australian based MR studio that designs amazing MR apps for Mining & Resources industry to improve their mining procedures, training and service.

Mixed Reality (MR) Mining & Resources Industry

Mixed Reality, particularly through the use of devices like the Microsoft Hololens 2, holds immense potential in the Mining & Resources sector. Field engineers can benefit from real-time holographic overlays that provide critical information on equipment, allowing them to visualise complex systems and perform maintenance tasks more efficiently. Training programs can be enhanced through immersive simulations that replicate real-world scenarios, enabling workers to gain hands-on experience without the need for physical equipment. This technology can improve safety by providing contextual guidance, reducing errors, and minimising downtime. The ability to collaborate remotely using Mixed Reality also allows experts to provide guidance and support from afar, optimising operational efficiency and minimising travel costs. Overall, Mixed Reality empowers the Mining & Resources sector with enhanced visualisation, training capabilities, and remote collaboration, leading to improved productivity and streamlined operations.

What are the benefits of MR for the mining & resources industry?

Training is much safer for employees

Workers can practice potentially dangerous procedures

Employees can more easily communicate with staff at headquarters

Documents and information are more readily to hand

Training is more efficient and can be completed quicker

The onboarding process is more successful

Allows predictions to be made based on previous data

Digital twins allow a better understanding of sites

Reduces human errors

Facilitates faster working and solutions

How MR is currently being used by mining & resources industry

Mixed reality is thought to be improving the productivity of workers as well as massively improving the onboarding process. MR safety training allows new employees to understand the nuances of the role and be prepared for any situation. Rather than just learning theory, they will be able to experience the events that may arise and therefore be more prepared to problem solve when it comes to real life.

For field engineers, MR offers a much more efficient line of contact between them and staff at headquarters. In enclosed spaces, MR allows workers to see necessary documents and information before them without having to drag physical items with them. When working at heights, MR can be used in a similar way, therefore improving safety.

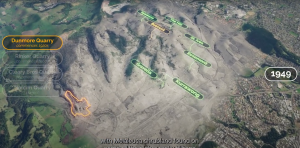

When working on a mine site, MR can be used to create a digital twin of the area, meaning workers will have a much better understanding of the space. This allows them to make predictions based on the previous knowledge they hold and therefore promotes efficient solutions but also improves safety elements of the role by ensuring that the actions workers are expected to undergo will not cause them any harm when it comes to working in the mine area.

Brainstorm your ideas on 1300 00 0092

The industries we work in

MR Mining & Resources

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

MR Mining & Resources Articles

MR Mining & Resources Videos

Frequently Asked Questions

How does MR improve data visualization and analysis in the resources industry?

MR provides a visual representation of complex mining data, such as geological information and operational metrics. It allows users to overlay data onto the physical environment, enabling better analysis, decision-making, and optimization of mining processes.

What are the benefits of using MR for remote collaboration in mining projects?

MR enables geographically dispersed teams to collaborate in a shared virtual environment, regardless of their physical locations. It enhances communication, facilitates design reviews, and enables stakeholders to make informed decisions without the need for costly travel.

Can MR be used for equipment maintenance and troubleshooting?

Absolutely. MR enables technicians to visualize and interact with 3D models of mining equipment, facilitating maintenance and troubleshooting tasks. It allows for remote assistance, step-by-step instructions, and faster problem-solving, reducing downtime.

How can MR improve safety training in the mining industry?

MR allows trainees to practice hazardous scenarios in a virtual environment, helping them develop critical safety skills without the risk. It also provides real-time feedback, tracks performance, and enhances situational awareness for better safety outcomes.

What is MR (Mixed Reality) and how is it used in the mining and resources industry?

MR combines virtual and augmented reality technologies to create immersive and interactive experiences. In mining and resources, MR is used for training simulations, remote collaboration, equipment visualization, and data visualization.