AR for Mining & Resources

3D Walkabout is an Australian based AR studio that designs amazing AR apps for Mining & Resources companies that fundamentally improve the way they train their workforce and engage clients.

Augmented Reality (AR) for Mining & Resources

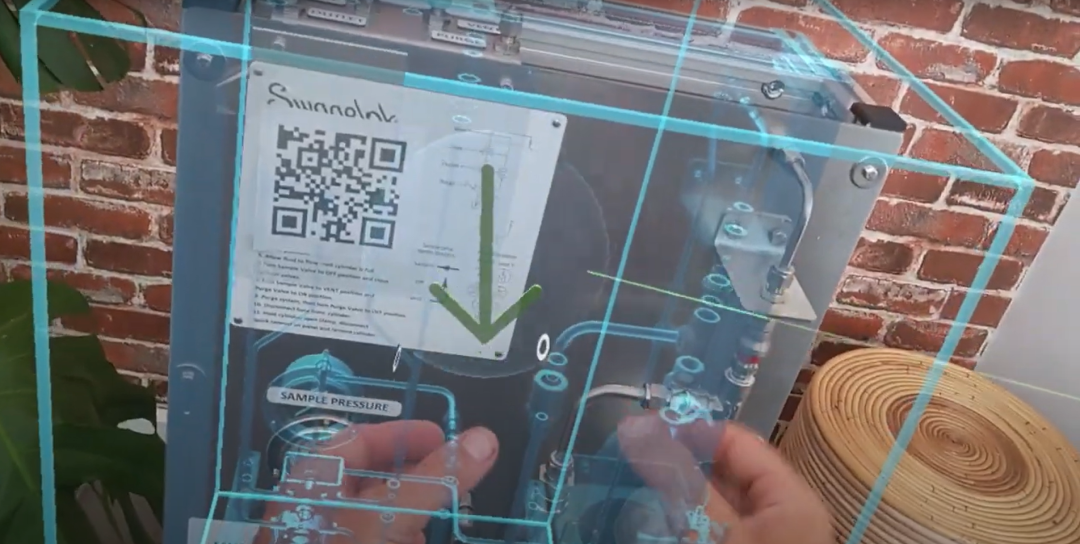

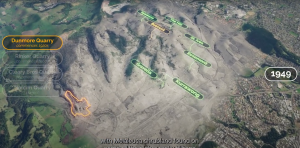

Augmented Reality (AR) is making significant strides in the Mining & Resources industry, offering a range of benefits and practical use cases. AR technology enables real-time overlay of digital information onto the physical environment, enhancing operational efficiency and safety. In mining, AR can be utilised for remote monitoring and visualisation of mining sites, allowing geologists and engineers to assess terrain, identify resources, and plan excavations. It also aids in equipment maintenance and repair by providing step-by-step instructions and digital overlays on machinery. Additionally, AR enhances worker training and safety by simulating hazardous scenarios and providing on-the-job guidance. The implementation of AR in the Mining & Resources industry streamlines operations, reduces downtime, and improves overall productivity and safety measures.

What are the benefits of AR for your business?

Workers can utilise an overlay of relevant data

Assists with ensuring the health and safety of workers

Increases productivity of those working on-site

Helps locate target areas for mining

Improves training for new workers

Assists with maintenance and repairs

Can be used to consult experts remotely

Holograms can display instructions and visual aids

It helps to minimise costs

It allows for increased communication between site workers and headquarters

How is AR currently being used by companies?

Within resources, AR is being widely used to improve the onboarding and training 🧑💻processes for new workers. AR training is a great way to build on current procedures to ensure that new employees are confident in their abilities before their skills are put to the test in the real world. This also includes AR safety 🦺 training, which allows workers to practise their responses to dangerous scenarios in a safe environment. Conducting training in this way has been shown to be more engaging, producing better results when it comes to performing tasks in reality and improving staff retention.

Mining is one of many industries with an ageing workforce, and for field engineers, AR can be an effective way to contact those with more experience and expertise for help. When working at a mine, AR allows an easy form of contact which doesn’t waste time during a difficult job. Further, when working in enclosed spaces, AR means workers can access plans without having to carry lots of extra equipment. In relation to safety, when working at heights 🪜, AR ensures workers can avoid accidents as they have both hands available due to any documents or information being projected for them through a hologram.

Brainstorm your ideas on 1300 00 3392

If you’d like to receive our full ‘AR for Mining & Resources Information Pack & Price List’ add your details below.

The industries we work in

AR Case Studies

News & Articles from our Blog

Worth a watch…

Frequently Asked Questions

How is AR being used on mine sites?

AR mobile apps using persistent AR can be used to add augmented markers and instructions on site equipment plus allow field engineers to update notes for the next user to find. It can remove the requirement for hand-written notes or the marking up of 2D plans. MR headsets allow users to work hands-free and view holographic instructions and annotations whilst communicating with an expert remotely.